Industrial Waste Shredder

Input Size : Customize.

Product Application : industrial waste disposal industry

Applicable Material : industrial waste, Waste blue drum, Waste paint bucket, solid waste etc.

Product Description

The industrial waste processing line developed by Xrido can transform industrial waste into high-quality high calorific value SRF/RDF, which can be used as fuel instead of fire coal, thus realizing the conversion of waste into energy. This processing line is mainly aimed at relatively pure waste leather, commercial waste plastics and other high calorific value solid waste, for more complex waste can be equipped with screen and density air sorting machine to complete the target to be processed. High torque double shearing shredder and special single shaft shredder for SRF/RDF will be used in the system. After secondary shredding, the material size can reach 30-80 mm (based on the requirement), and the standard-reaching rate is higher than 95%.

Everything can be shredded

Applicable Industrial Waste Shredder Material:

-

Industrial waste

-

Industrial waste

-

Wood waste

-

Plastic waste

-

Waste paper

-

Waste cloth/textile

-

Waste leather product

-

Waste leather scraps

The Double Shaft Shredder adopts dual-shaft independent drive, so that during production, the material is pressed accordingly, and the automatic feeding function is achieved. There will be no phenomenon of shaft wrapping or jamming of the equipment, thus improving the production efficiency. The equipment is suitable for the crushing of various tough and viscous materials.

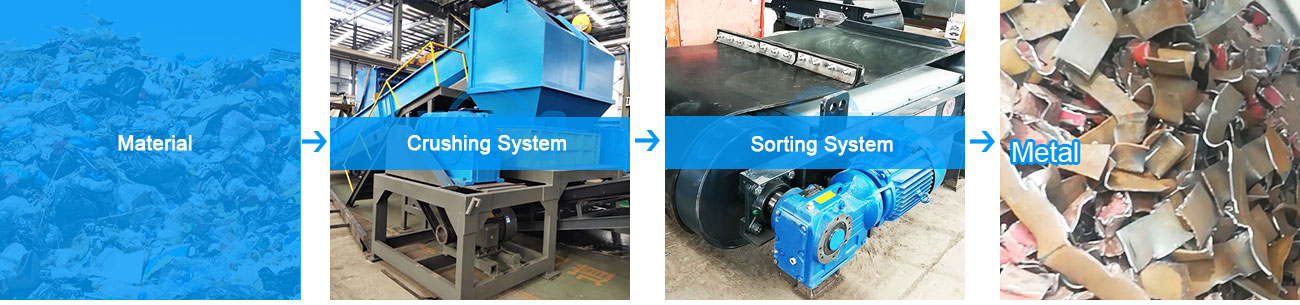

Industrial Waste processing system:

The solid waste disposal system can be customized according to the actual materials.

WORKING PRINCIPLE

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out;

2.Double shaft cutting system:Using different blades according customer's materials;

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs;

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

Details of Industrial Waste Shredder

FINAL PRODUCT

Discharge particle size can be customized.

Case of Industrial Waste processing system:

Technical Parameters

| Model | Power (KW) | Rotating speed (r/min) | Dimensions L/W/H(mm) | Crushing cavity size C/D(mm) | Diameter of knife body (mm) |

| XCS-56 | 15+15 | 6-20 | 2800×1300×1850 | 600×500 | 220 |

| XCS-58 | 18.5+18.5 | 6-20 | 3000×1300×1850 | 800×500 | 220 |

| XCS-710 | 30+30 | 6-20 | 3300×1900×2200 | 1000×700 | 320 |

| XCS-812 | 37+37 | 6-20 | 3600×2000×2200 | 1200×800 | 400 |

| XCS-815 | 45+45 | 6-20 | 4180×2100×2400 | 1500×850 | 450 |

| XCS-918 | 75+75 | 6-20 | 5800×2400×3300 | 1800×900 | 500 |

| XR-1020 | 90+90 | 6-20 | 6400×2700×3500 | 2000×1000 | 600 |

| XR-1522 | 110+110 | 6-20 | 7800×3200×3800 | 2200×1500 | 800 |