Metal Shredder Machine

All metal materials contain valuable,Customizable recycling solutions.

Applicable Material : Scrap metal, Scrap steel, Scrap iron, Scrap aluminum, Scrap radiator, Scrap copper, paint drums, diesel drums, thin iron sheets, car shells, metal briquettes, metal plate scraps etc.

Product Description

Reliable and durable recycling technologies for material separation and recovery,treatment of various types of solid waste and metal scrap. Metal recycling can benefit your Enhance and economic value , Help you improve recycling eliminate landfilling of waste.

With XRIDO’s ready-to-use spare parts library , you gain peace of mind through seamless maintenance and reduced downtime.

Products Show

The output particles after shredding scrap metal can be customized.

-

Metal Crusher

-

Metal Shredder

-

Metal Shearing Machine

-

Scrap Metal Crushing Plant

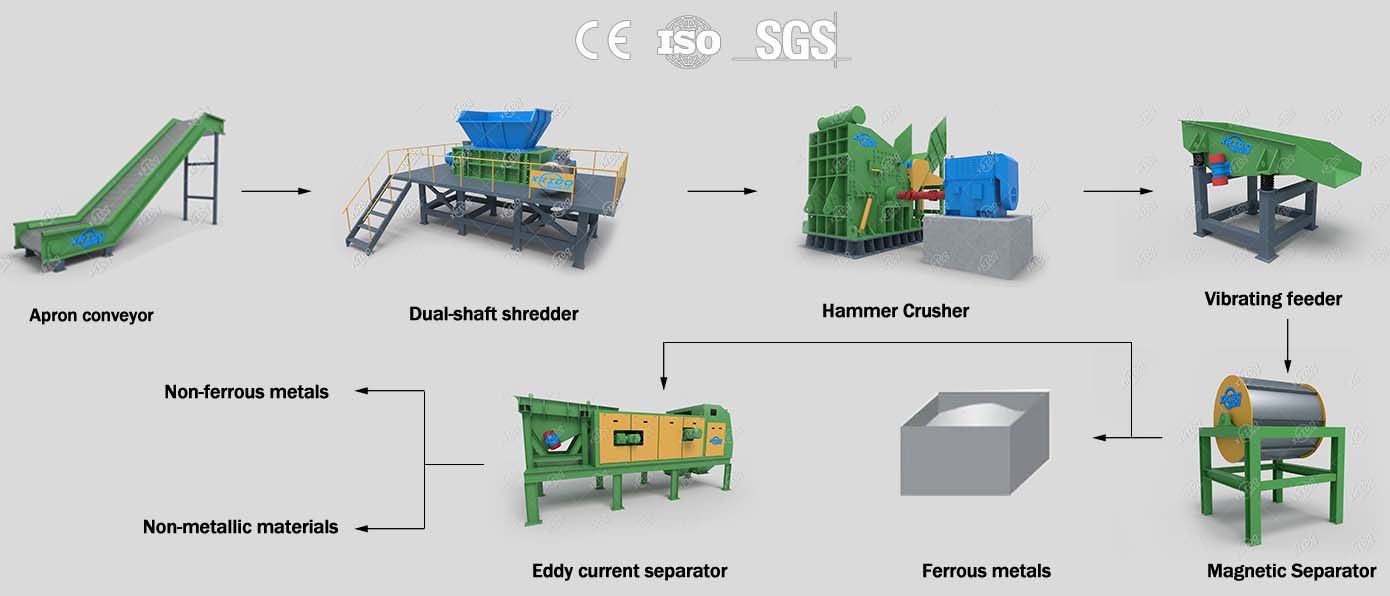

Scrap Metal Crushing Recycling Line

1.metal recycling line adopts two-shaft metal shredder, hummer crusher for crushing the scrap metel.

2.Use Dust collector and special structures to remove the fine particle and dust during the crushing period.

3.The scrap metal recycling equipment separates the ferrous metal by a magnetic separator.

4.A vortex separator is adopted by the waste recycling machine to separate the non-ferrous metal from nonmetal materials. Conduct innocent treatment by removing dust in concentrated air and filtering the gas by activated carbon.

Core equipment:Double-Shaft Shredder ,Hammer crusher ,Magnetic Separator, Eddy current separator.

Profitable, Efficient and Reliable

Our R&D and manufacturing base covers 20,000 square meters land,We are manufacturer,We can customize metal crushing and recycling production line for you.

Applicable materials

The Xrido plant range offers recycling solutions for a wide variety of different applications: Electronic and electrical waste, refrigerators, cable scrap, aluminum scrap,metal scrap.The metal shredder is mainly used for crushing scrap metal, increasing its bulk density for transportation and recycling.

Cases of the Metal Shredder

Other Metal Recycling Machine

Scrap Metal Recycling and Sorting Line

About Double-shift Shredder

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out;

2.Double shaft cutting system:Using different blades according customer's materials;

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs;

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

The Video

Technical Parameters

| Model | Power (KW) | Rotating speed (r/min) | Dimensions L/W/H(mm) | Crushing cavity size C/D(mm) | Diameter of knife body (mm) |

| XCS-56 | 15+15 | 6-20 | 2800×1300×1850 | 600×500 | 220 |

| XCS-58 | 18.5+18.5 | 6-20 | 3000×1300×1850 | 800×500 | 220 |

| XCS-710 | 30+30 | 6-20 | 3300×1900×2200 | 1000×700 | 320 |

| XCS-812 | 37+37 | 6-20 | 3600×2000×2200 | 1200×800 | 400 |

| XCS-815 | 45+45 | 6-20 | 4180×2100×2400 | 1500×850 | 450 |

| XCS-918 | 75+75 | 6-20 | 5800×2400×3300 | 1800×900 | 500 |

| XCS-1020 | 90+90 | 6-20 | 6400×2700×3500 | 2000×1000 | 600 |

| XCS-1522 | 110+110 | 6-20 | 7800×3200×3800 | 2200×1500 | 800 |