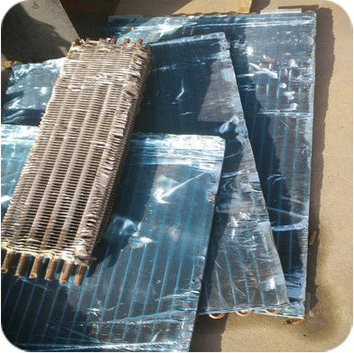

Raw materials: Car water tank , Air conditioner radiator , single layer , double layer ,four layer Multi layer radiator

Radiator scrap aluminum copper recycling plant is used to different kinds of the radiator scrap through the conveyor to double shaft shredder ,outcomes goes to the hammer crusher , end products as ball size , the iron will be sorted by suspend magnetic. Dust will be collected by the impulse dust catcher , dust exits from cyclone.

Then feeding to vibration screen to sort the big particle size, which is not suitable to gravity separator machine . back to the vertical crusher . gravity separator machine will sort the copper from the aluminum . the purity is surpass 99%.

Raw materials: Car water tank , Air conditioner radiator , single layer , double layer ,four layer Multi layer radiator

Processing capacity: 500Kg / h, 8 hours a day

Power consumption: 62kw / H

Worker: 2 workers

Global raw materials prices are roughly the same, taking the Chinese market as an example to make a profit analysis.

This copper aluminum radiator recycling machine is specially designed for processing the scrap radiators which are broken and deformed, which are not available to be processed by the stripping type radiator separator machine.

Characters:

1.Full automatic line, the whole system controlled by PLC.

2.High efficient , workers 2-3 . energy saving 1/3 than traditional method.

3.Scientific designed for whole line . which is easy and convenient to repair or exchange spare part .

4.crusher takes vertical crusher type rotor alternately ranking. Which is much more durable and tough. Low rotary speed , high torque , easy operation , little noise.

5.whole system assembled with impulse dust catcher to avoid dust pollution .

| Type | Power (Kw) | Capacity (kg/h) | Process range | Overall size |

| XRIDO800 | 60-90 | 500-800 | Under 800mm | 15000*8000*4000mm |

| XRIDO1500 | 110-150 | 1000-1500 | Under 1500mm | 20000*11000*4000mm |

| Tips : The whole system could be flexible installation as customer workshop . The overall size is calculated as installing as line | ||||