C&D Waste Sorting Recyling Line

Capacity : as customer requirement how many sets annually .

Applicable Material : Domestic Waste, Urban trash , Landfill Stale Waste, Municipal Solid Waste, Construction and Demolition Waste, Scrap Metal, Industrial Waste, Plastic Waste, Solid Waste

Product Description

The c&d waste sorting recycling system can sort waste cloth, plastic bags and other sundries in the c&d waste recycling aggregate, and can also clear out large and medium-sized wooden blocks and plastic stool waste. After two screenings, the impurity separation rate reached 98%. Among them, concrete and waste rock are used to produce coarse and fine aggregates, which can be used to produce concrete and mortar of corresponding strength levels or to prepare building materials such as blocks, wall panels, and floor tiles.

After adding cured material to coarse and fine aggregate, it can also be used for the base course of road pavement. Waste bricks and tiles are used to produce aggregates, which can be used to produce recycled bricks, blocks, wall panels, floor tiles and other building materials. The muck can be used for road construction, pile filling, foundation, etc. Abandoned wood construction waste and undamaged wood can be directly reused in other places, and severely damaged wood components can be used as raw materials for recycled wood to make cardboard or paper.

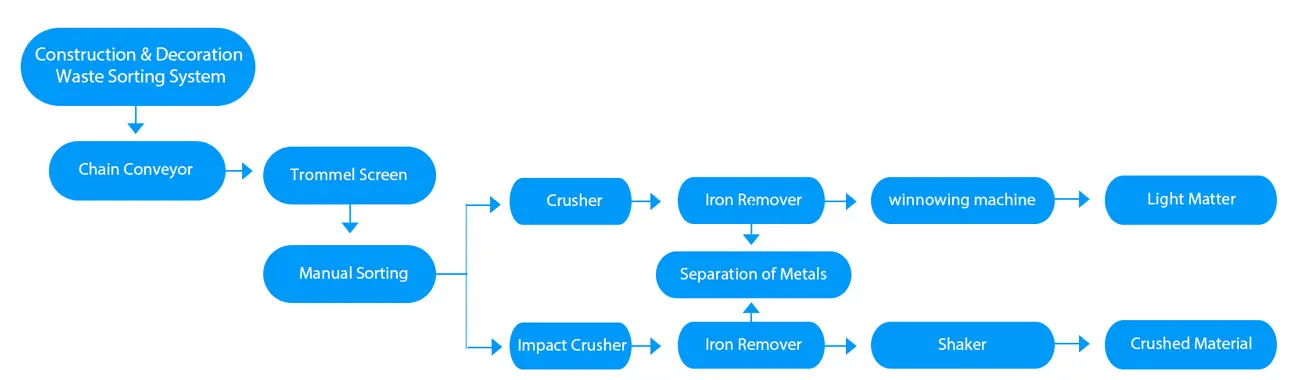

Garbage Recycling Sorting Process:

The production line machine is configured according to the actual situation of the customer.

C&D waste sorting recycling system is through a series of processes such as conveyor, winnowing machine, drum screen, magnetic vortex sorting machine, winnowing, dust collection and gas treatment. Separate copper, aluminum and non-ferrous metals, iron and magnetic materials, plastic rubber, stainless steel, heavy sand and gravel, organic matter and sundries, and large clothes in the original materials. The purity can reach about 98%. The process is fully automated from feeding to sorting, with a daily processing capacity of 300-500 tons, requiring only a small amount of manual operation.

1. Construction and decoration waste sorting equipment does not require fire, chemical raw materials, and water. A new technological process that replaces the original pollution methods such as manual, fire, water separation or landfill..

2. According to the production needs of customers, we can customize and design a complete construction and decoration waste equipment treatment system solution.

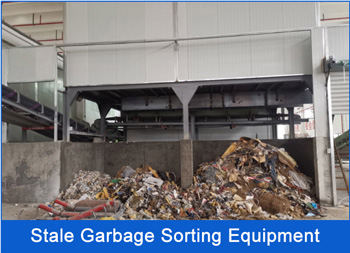

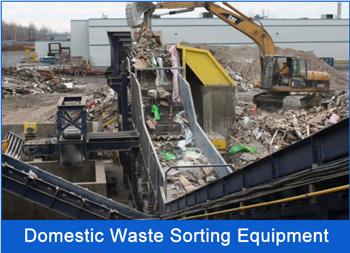

3. It is mainly used for the extraction and sorting of recyclable materials such as urban domestic waste, industrial waste, construction waste, decoration waste, and stale waste..

Materials suitable for the sorting and recycling system:

Applicable of Waste Sorting System

√Domestic Waste, Urban trash

√Landfill Stale Waste

√Municipal Solid Waste

√Construction and Demolition Waste

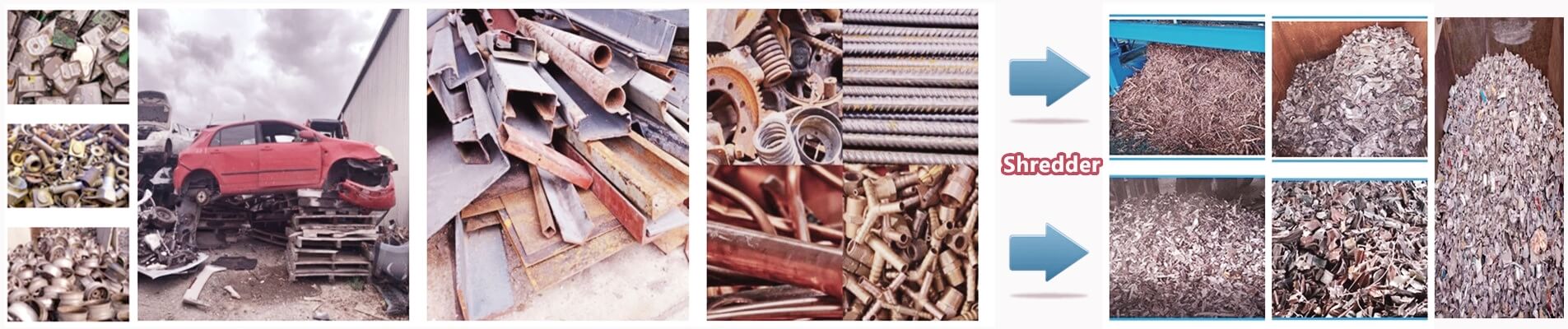

√Scrap Metal, Industrial Waste

√Plastic Waste, Solid Waste

Customer Site - Sorting and Recycling Plants:

Working Process of Waste Sorting Plant:

1. The garbage will be transported to the feeding platform by forklift, and the garbage will be carried away by hopper.

2. The garbage is evenly distributed by the feeder, and then evenly sent to the next process by the belt conveyor.

3. When the garbage passes through the sorting platform, the larger garbage will be picked out.

4. Waste will be separated by rotary screening machine can be customized according to customer requirements.

5. The plastic will be packed by the baler; Heavy materials will be sent directly to the outside landfill or pulverized to make bricks; We can pick out useful materials from the mix and then recycle them.

6. All garbage sorting equipment in the garbage sorting line can be customized according to the actual needs of customers.