Scrap Copper Aluminum Crusher

Input Size : Customize

Output Capacity : 0.5-10T/H

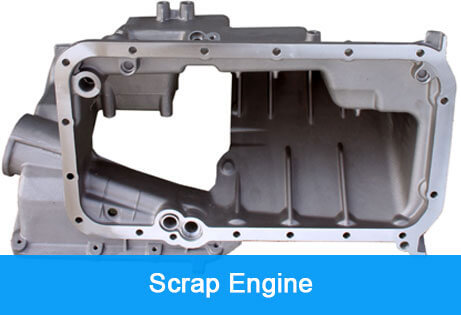

Applicable Material : Scrap aluminum alloy, Scrap engine, Scrap radiator, Broken bridge aluminum, Water tank, Copper wire, Air conditioner radiator, Copper and aluminum plate and other scrap metal materials.

Product Description

XRIDO serious Metal Crusher for Copper aluminum is for tough and hard metal waste . through the motor driving the shaft to achieve decrease size into small chip . working with high torque low speed by reducer. Its ideal equipment for metal shearing ,crushing ,tearing ,metal refining company optional.

The Scrap Copper Aluminum Crusher is is mainly used for crushing Scrap aluminum alloy, Scrap engine, Scrap radiator, Broken bridge aluminum, Water tank, Copper wire, Air conditioner radiator, Copper and aluminum plate and other scrap metal materials. After the radiator is shredded, different kinds of metals can be sorted. This equipment is widely used in shredding car water tank radiator, air conditioner radiator, copper and aluminum plate, and other scrap metal materials.

We can customize waste copper aluminum crushing and recycling production line for you.

Products Show

The output particles after shredding scrap metal can be customized.

-

Metal Crusher

-

Metal Shredder

-

Metal Shearing Machine

-

Aluminum UBC Cans Shredding & Decoating Plant

Applicable materials

The Scrap Copper Aluminum Crusher is mainly used for crushing Scrap aluminum alloy, Scrap engine, Scrap radiator, Broken bridge aluminum, Water tank, Copper wire, Air conditioner radiator, Copper and aluminum plate and other scrap metal materials.

Crushed material

The output particles after shredding scrap metal can be customized.

Metal Crushing Recycling Plant

We can customize metal crushing and recycling production line for you.

-

UBC Aluminum Cans Decoating Machine

-

Waste Aluminum Crushing Production Line

-

Water Radiator Crushing Sorting Line

-

Scrap Metal Shredder Sorting Line

Cases of the Metal Crusher

WORKING PRINCIPLE

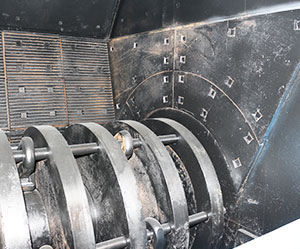

The material is broken by the mutual shear and tearing principle between two relatively rotating tools.It works with the characters of low speed ,large torque and high shear force,good tearing effect ,small noise good operating stability ,thus achieve the strong working power ,and high operating stability .

FEATURES

● Low speed, large torque, Low noise, low dust;

● Hydraulic feeding system, swinging arm forced feeding structure; 180° turnover, the knife body utilization rate is higher;

● Reduction gearbox swinging arm installation structure, micro switch monitoring, protect the internal gear and motor;

● Imported SKD11, D2, DC53, ASP60 blades, high strength, wear resistance, long life;

● Feeding test for 80~100 hours before delivery to ensure the reliability of the equipment.

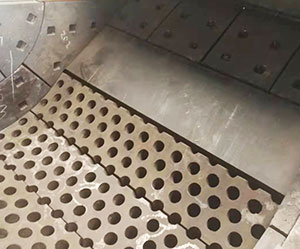

SHREDDER KNIFE ACCESSORIES

Technical Parameters

| Model | Power (KW) | Rotating speed (r/min) | Dimensions L/W/H(mm) | Crushing cavity size C/D(mm) | Diameter of knife body (mm) |

| XR-56 | 15+15 | 6-20 | 2800×1300×1850 | 600×500 | 220 |

| XR-58 | 18.5+18.5 | 6-20 | 3000×1300×1850 | 800×500 | 220 |

| XR-710 | 30+30 | 6-20 | 3300×1900×2200 | 1000×700 | 320 |

| XR-812 | 37+37 | 6-20 | 3600×2000×2200 | 1200×800 | 400 |

| XR-815 | 45+45 | 6-20 | 4180×2100×2400 | 1500×850 | 450 |

| XR-918 | 75+75 | 6-20 | 5800×2400×3300 | 1800×900 | 500 |

| XR-1020 | 90+90 | 6-20 | 6400×2700×3500 | 2000×1000 | 600 |

| XR-1522 | 110+110 | 6-20 | 7800×3200×3800 | 2200×1500 | 800 |