Double Shaft Shredder

Type: Waste Shredder, Metal Shredder.

Applicable Material : Industrial waste, Solid waste, Domestic waste, Scrap metal, Scrap Aluminum, Scrap Steel, Scrap Copper, etc.

Product Description

The Double Shaft Shredder can meet the waste recycling requirements of various industries, and is suitable for shredding thick and difficult materials, such as: electronic waste, plastic, metal, wood, waste rubber, packaging barrels, pallets, etc. There are many kinds of recyclable materials, and the shredded materials can be directly recycled or further refined according to demand. Suitable for industrial waste recycling, medical recycling, electronic manufacturing, pallet manufacturing, wood processing, household waste recycling, plastic recycling, tire recycling, papermaking and other industries. This series of double-shaft shredders have the characteristics of low speed, high torque and low noise. It adopts PLC control system and can be automatically controlled. It has the functions of start, stop, reverse and overload automatic reverse control.

Waste Disposal System

The Waste Disposal System can be customized according to the actual materials.

Solid Waste Disposal Line

Core equipment:

Case 1.Primary crusher,Separator System ,Shredder/fine crusher,RDF Forming Machine .

Case 2.Primary crusher, Separator System, baler machine.

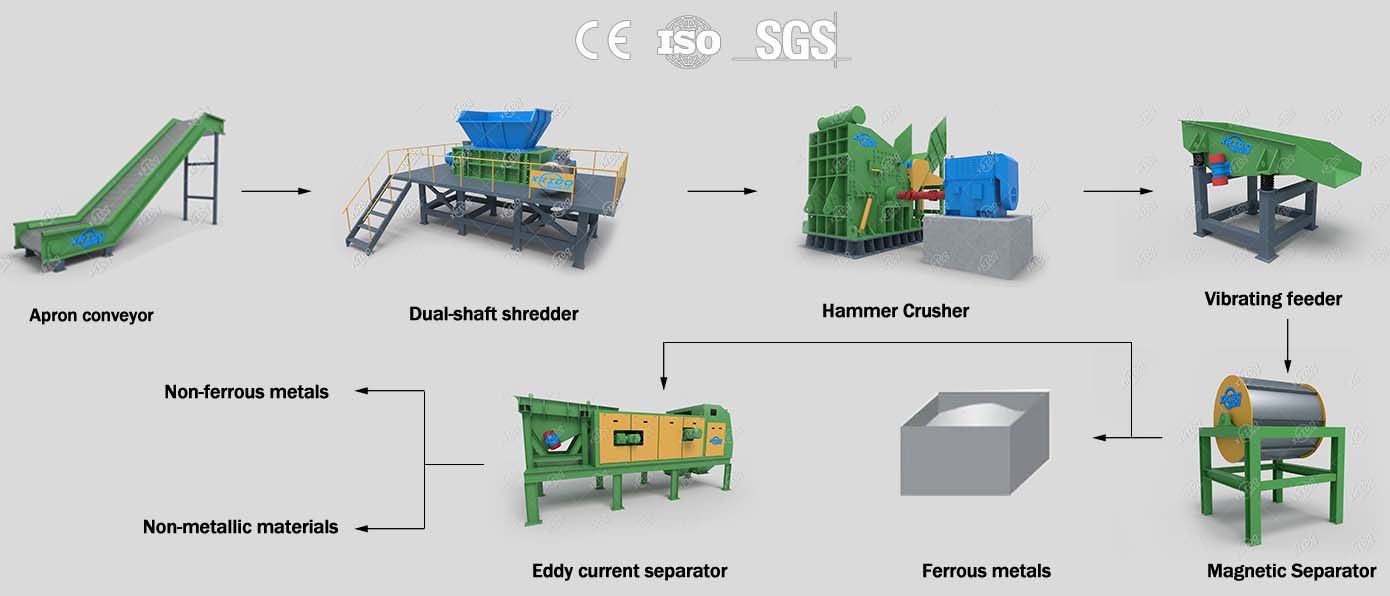

Scrap Metal Recycling line

Core equipment: Double Shaft Shredder ,Hammer crusher ,Magnetic Separator, Eddy current separator.

Everything can be shredded

Applicable Double Shaft Shredder Material:

The Double Shaft Shredder adopts dual-shaft independent drive, so that during production, the material is pressed accordingly, and the automatic feeding function is achieved. There will be no phenomenon of shaft wrapping or jamming of the equipment, thus improving the production efficiency. The equipment is suitable for the crushing of various tough and viscous materials.

Providing one-stop Solution

The company's main products include double-axis shredders, metal crushers, solid waste disposal equipment and renewable resource equipment to meet the needs of different customers. By providing a one-stop solution, XRIDO Group can helps customers solve various solid waste treatment problems.

Solid Waste Disposal Machine Show:

-

Shredder Machine

-

Crusher Machine

-

RDF Machine

-

Baler Machine

APPLICABLE

1. All kinds of hollow containers: plastic beverage cans, plastic buckets, iron drums, packing boxes, packing drums;

2. Used household appliances: TV, washing machine, refrigerator shell;

3. Pipe material: large pipe, pipe fitting and PE pipe;

4. Used templates: wooden pallets, plastic pallets and forklifts;

5. Used tires: car tires, truck tires;

6. Scrap metal: automobile housing, aluminum alloy, scrap cast aluminum parts, engine housing, lead and steel plates with thickness below 5mm;

7. Cooking garbage, living garbage, RDF derivative, medical waste, biological orange pole, garden garbage;

8. Glue head material, paper mill rope.

FINAL PRODUCT

Discharge particle size can be customized.

WORKING PRINCIPLE

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out;

2.Double shaft cutting system:Using different blades according customer's materials;

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs;

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

Details of double shaft shredder

FEATURES

1, High performance, strong powerful and high speed crushing.

2, Motor with overload protection device.

3, Supply chain environmental protection system, ensure safe operation.

4, Easy disassembly design, convenient clean-up and repair.

5, Minicomputer with a four-wheel for easy mobility.

6, More than 20HP plastic crusher is equipped with cooling system.

7, Suitable for recycle and restore of all kinds of plastic, particulary for various hard plastic, e.g. blow molded products and shoel last.

The Video

Technical Parameters

| Model | Power (KW) | Rotating speed (r/min) | Dimensions L/W/H(mm) | Crushing cavity size C/D(mm) | Diameter of knife body (mm) |

| XCS-56 | 15+15 | 6-20 | 2800×1300×1850 | 600×500 | 220 |

| XCS-58 | 18.5+18.5 | 6-20 | 3000×1300×1850 | 800×500 | 220 |

| XCS-710 | 30+30 | 6-20 | 3300×1900×2200 | 1000×700 | 320 |

| XCS-812 | 37+37 | 6-20 | 3600×2000×2200 | 1200×800 | 400 |

| XCS-815 | 45+45 | 6-20 | 4180×2100×2400 | 1500×850 | 450 |

| XCS-918 | 75+75 | 6-20 | 5800×2400×3300 | 1800×900 | 500 |

| XR-1020 | 90+90 | 6-20 | 6400×2700×3500 | 2000×1000 | 600 |

| XR-1522 | 110+110 | 6-20 | 7800×3200×3800 | 2200×1500 | 800 |