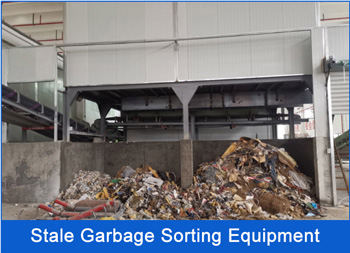

Landfill Stale Waste Sorting Line

Capacity : as customer requirement how many sets annually .

Applicable Material : Domestic Waste, Urban trash , Landfill Stale Waste, Municipal Solid Waste, Construction and Demolition Waste, Scrap Metal, Industrial Waste, Plastic Waste, Solid Waste

Product Description

Stale garbage is mainly due to the fact that after years of microbial decomposition, the fermentation water is relatively large, which makes the content of organic matter extremely low. The stale garbage needs to be dug out before screening, and part of the separated combustibles will be used for garbage incineration. A part is composted and landfilled.

The sorting purity of the above garbage can reach more than 85%, and the sorting purity of film plastics can reach more than 90%, laying a solid foundation for the "recycling and industrialization" of waste treatment process.

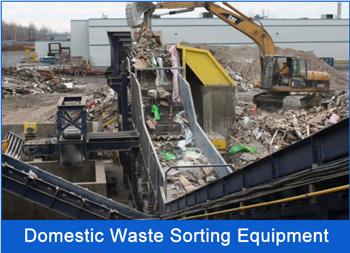

Customer Site - Sorting and Recycling Plants:

Materials suitable for the sorting and recycling system:

Working Process of Waste Sorting Plant:

1. The old garbage is transported into the garbage treatment plant by the transport vehicle, and then unloaded to the feeding workshop after being weighed and measured. The loader pushes the garbage into the apron feeder, and the apron feeder sends the garbage into the homogenizer. After the feeder, the belt conveyor will send the garbage into the drum screen for mechanical screening;

2. After being screened by the trommel screen, the material on the screen is a material with a large particle size, which is lifted by the belt conveyor and sent to the air separator for wind separation. The light material is blown out and falls on the light material receiving conveyor. The material belt conveyor transports the baler, and is pulled away by the transport vehicle after baling;

3. The heavy material directly falls on the heavy material receiving conveyor due to gravity, and is transported to the transport vehicle by the discharge belt conveyor to be pulled away. The undersize is materials with small particle size, generally lime soil, which is transported from the receiving conveyor to the transfer conveyor, unloaded on the transport vehicle, transported away, and made into humus.

Applicable of Waste Sorting System

√Domestic Waste, Urban trash

√Landfill Stale Waste

√Municipal Solid Waste

√Construction and Demolition Waste

√Scrap Metal, Industrial Waste

√Plastic Waste, Solid Waste

FINAL PRODUCT

Case of Waste Sorting System

Technical Parameters

| Model | XRD-100D | XRD-200D | XRD-400D |

| Raw materials | Domestic Waste, Urban trash , Landfill Stale Waste, Municipal Solid Waste, Construction and Decoration Waste, Scrap Metal, Industrial Waste, Plastic Waste, Solid Waste | ||

| Capacity | 100T/D | 200T/D | 400T/D |

| Power | 149KW | 224.7KW | 279KW |

| Area | 2400㎡ | 2800㎡ | 3000㎡ |

| Working time | 20 hours | 20 hours | 20 hours |