Metal Crocodile Shear

Input Size : Customize

Output Capacity : 200-10000kg/h

Applicable Material : Light and thin materials, Medium waste, Heavy waste, Steel bars, etc.

Product Description

The crocodile shearing machine is suitable for metal recycling processing plants, scrap car dismantling plants, smelting and casting industries, scrap steel plants, etc. It can cut various shapes of steel and various metal materials in cold state. The crocodile shearing machine is based on its structural principle. Similar to the crocodile, it is named after the crocodile. Because of its simple design structure, low failure rate, high shear pressure, and low maintenance cost, it has been unanimously recognized by the market.

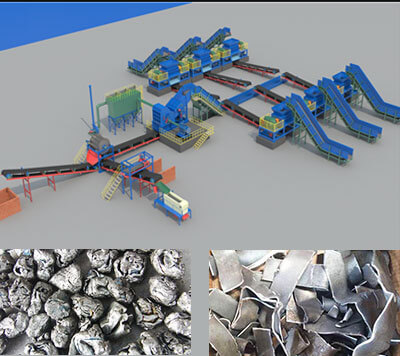

Key equipment of metal crushing and recycling production line:

-

Metal Crusher

-

Metal Shredder

-

Metal Shearing Machine

-

Scrap Metal Crushing Plant

Applicable materials:

The crocodile shearing machine is suitable for metal recycling processing plants, scrap car dismantling plants, smelting and casting industries, scrap steel plants, etc. It can cut various shapes of steel and various metal materials in cold state.

√ Iron cuttings,sheet iron, sheet steel

√ Copper cuttings, sheet copper, Steel cuttings

√ Scrap iron bar, Waste steel wire

√ Waste wire, Waste steel pipe

√ Scrap metal, Scrap iron pipe

Metal crusher is suitable for crushing scrap steel, scrap iron, scrap aluminum and other metals. The metal crusher can be scientifically customized according to the crushed materials and processing capacity.

Metal Crushing Recycling Plant

We can customize metal crushing and recycling production line for you.

-

Scrap Metal Shredder Sorting Line

-

Waste Aluminum Crushing Production Line

-

Water Radiator Crushing Sorting Line

-

Scrap Steel Crushing Recycling Line

Cases of the Metal Shearing Machine

WORKING PRINCIPLE

The metal crocodile shearing machine is a pair of upper and lower crocodile shearing machines. The working principle is to create pressure driven by a hydraulic pump. Under the control of the electromagnetic reversing valve and oil circuit, the oil cylinder can rise and contract. The upper crocodile knife and the lower crocodile fixed knife realize interactive shearing of the material entering the incision under the continuous pushing action of the main oil cylinder.

Technical Parameters

| Shearforce (tons) | Pressingforce (tons) | Bladelength (mm) | Shearmouthheight (mm) | Shearfrequency (times/PM) | Shearmaterialsspecification (mm) |

| 63 | 16 | 600 | 280 | 9-16 | 30X30 Ø35 |

| 100 | 16 | 600 | 280 | 9-16 | 40X40 Ø45 |

| 120 | 20 | 600 | 280 | 9-16 | 45X45 Ø50 |

| 160 | 25 | 700 | 320 | 9-16 | 55X55 Ø63 |

| 200 | 25 | 800 | 380 | 9-16 | 65X65 Ø75 |

| 250 | 26 | 1000 | 480 | 9-16 | 70X70 Ø80 |

| 315 | 42 | 1200 | 520 | 8-16 | 80X80 Ø90 |

| 400 | 42 | 1500 | 700 | 8-16 | 90X90 Ø100 |

| 500 | 42 | 1800 | 900 | 8-16 | 100X100 Ø110 |