Metal Crushing Sorting Line

Input Size : Customize.

Product Application : Scrap metal Recycling industry

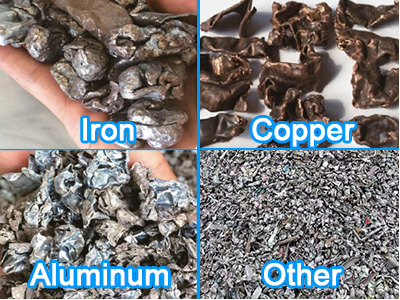

Applicable Material : Sorting of Scrap metal, Scrap steel, Scrap iron, Scrap aluminum, Scrap radiator, Scrap copper, paint drums, diesel drums, thin iron sheets, car shells, metal briquettes, metal plate scraps and other metal materials after crushing

Product Description

The metal crushing and sorting production line is a metal recycling production line used to process and decompose various copper, aluminum, and iron waste materials. The composite waste containing copper, aluminum, plastic, rubber, stainless steel foam, and the like can be discharged from different materials in sequence after being processed by the metal crushing and sorting production line. The net content of the finished material is 92%-99%.

Metal crushing and sorting process:

The output particles after shredding scrap metal can be customized.

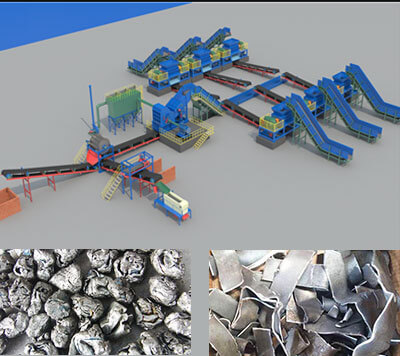

The metal crushing and sorting production line is mainly composed of: shredding (large to small), crushing (material separation), conveying, screening and other equipment; the metal crushing and sorting production line can be divided into large, medium and small according to production capacity and cleanliness requirements, with output ranging from It ranges from a few hundred kilograms to several tons per hour.

Applicable materials

The metal shredder is mainly used for crushing scrap metal, increasing its bulk density for transportation and recycling.

This equipment is widely used in shredding paint drums, diesel drums, thin iron sheets, car shells, metal briquettes, metal plate scraps and other scrap metal materials.

Metal Crushing Recycling Plant

We can customize metal crushing and recycling production line for you.

-

Scrap Metal Shredder Sorting Line

-

Waste Aluminum Crushing Production Line

-

Water Radiator Crushing Sorting Line

-

Scrap Steel Crushing Recycling Line

Cases of the Metal Shredder

The operation process of the equipment is that it takes 10-60 seconds for the crushed materials to be discharged from the crushing port. Fundamentally speaking, all scrap steel processing methods are the crushing of scrap steel. The so-called crushing is to process scrap steel of various shapes into finished scrap steel products that meet the furnace smelting standards to facilitate smelting. The metal crushing and sorting production line is a kind of equipment that can crush light materials, iron barrels, scrap bicycles, motorcycles, car casings, iron sheets, color steel tiles, scrap household appliances, various types of scrap steel, scrap iron, scrap aluminum, scrap iron and other scrap metals. Reused machinery and equipment.

Technical Parameters

Solutions can be customized according to customer needs.

| Model | Voltage | Power(kw) | Capacity(t/h) | Configure auxiliary machines |

| XD-140 | 380v | 132 | 2-3 | Feeding conveyor 1 set Output conveyor 1 set Steel conveyor 1 set Impurity conveyor 1 set Magnetic separation system 1 set Dust removal system 1 set PLC system 1 set Intelligent visual system (optional) 1set Spray system (optional) 1set |

| XD-200 | 380v | 200 | 3-5 | |

| XD-280 | 380v | 280 | 4-7 | |

| XD-315 | 380v | 315 | 5-8 | |

| XD-450 | 380v | 450 | 8-12 | |

| XD-630 | 10kv | 630 | 10-15 | |

| XD-750 | 10kv | 750 | 12-17 | |

| XD-800 | 10kv | 800 | 15-20 | |

| XD-900 | 10kv | 900 | 20-30 | |

| 1500hp | 10kv | 1200 | 25-40 | |

| 2000hp | 10kv | 1500 | 50-60 | |

| 3000hp | 10kv | 2250 | 60-80 | |

| 4000hp | 10kv | 3000 | 80-100 | |

| 6000hp | 10kv | 4420 | 100-160 | |

| 8000hp | 10kv | 6000 | 160-200 | |

| 10000hp | 10kv | 7500 | 200-260 |