Scrap Car Crusher

Input Size : Customize

Output Capacity : 2-260t/h

Applicable Material : Car body, scrap aluminum, scrap steel, scrap iron, paint bucket, color steel tile, iron pressure block, motorcycle frame, bicycle frame, waste household appliances, carriage plate, keel bar, rolling gate, waste angle iron and other waste metals.

Product Description

In car recycling business, normally the motors, transmissions, axles , hub and wheels are removed in advance, because as valuable parts, they can be sold at a higher price, and some parts can be used for maintenance use.

When these are moved, the car body can be shredded into metal fractions, even with further processing to make them into dense metal, all these can be sold to steel mill to be melted and reuse again.

Products Show

The output particles after shredding scrap metal can be customized.

-

Metal Crusher

-

Metal Shredder

-

Metal Shearing Machine

-

Scrap Metal Crushing Plant

Applicable materials

The metal shredder is mainly used for crushing scrap metal, increasing its bulk density for transportation and recycling.

This equipment is widely used in shredding Car body, scrap aluminum, scrap steel, scrap iron, paint bucket, color steel tile, iron pressure block, motorcycle frame, bicycle frame, waste household appliances, carriage plate, keel bar, rolling gate, waste angle iron and other waste metals.

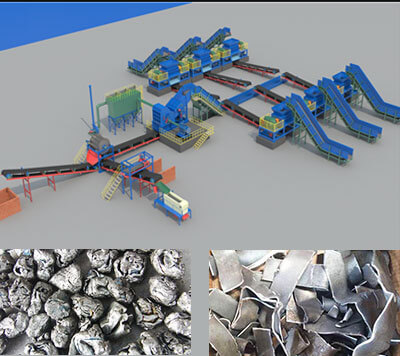

Metal Crushing Recycling Plant

We can customize metal crushing and recycling production line for you.

-

Scrap Metal Shredder Sorting Line

-

Waste Aluminum Crushing Production Line

-

Water Radiator Crushing Sorting Line

-

Scrap Steel Crushing Recycling Line

Cases of the Metal Crusher

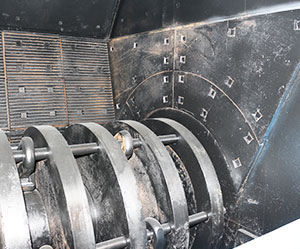

WORKING PRINCIPLE

The scrap steel shredder blade is made of the high-strength alloy steel,with the characters of strong wear resistance and high strength,etc.differential operation between the shafts,equipped with the function of tearing,extrusion,bite,etc.It is professional designed for the scrap steel crushing,with the advantages of uniform output,large output,small noise.

FEATURES

● Low speed, large torque, Low noise, low dust;

● Hydraulic feeding system, swinging arm forced feeding structure; 180° turnover, the knife body utilization rate is higher;

● Reduction gearbox swinging arm installation structure, micro switch monitoring, protect the internal gear and motor;

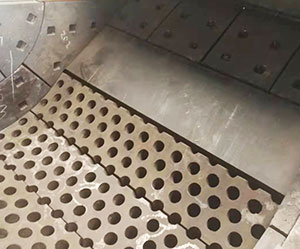

● Imported SKD11, D2, DC53, ASP60 blades, high strength, wear resistance, long life;

● Feeding test for 80~100 hours before delivery to ensure the reliability of the equipment.

SHREDDER KNIFE ACCESSORIES

Technical Parameters

| Model | Voltage | Powerkw) | Production capacity (t/h) | Configure auxiliary machine |

| PSJ-140 | 380V | 132 | 2-3 | 1 feeding conveyor

1 discharge conveyor 1 iron conveyor 1 impurity conveyor 1 magnetic separation system 1 dust removal system Intelligent visualization system (optional 1 set) Set of spray system (optional 1 set) |

| PSJ-200 | 380V | 200 | 3-5 | |

| PSJ-280 | 380V | 280 | 4-7 | |

| PSJ-315 | 380V | 315 | 5-8 | |

| PSJ-450 | 380V/10KV | 450 | 8-12 | |

| PSJ-630 | 10KV | 630 | 10-15 | |

| PSJ-750 | 10KV | 750 | 12-17 | |

| PSJ-800 | 10KV | 800 | 15-20 | |

| PSJ-900 | 10KV | 900 | 20-30 | |

| 1500horsepower | 10KV | 1200 | 25-40 | |

| 2000horsepower | 10KV | 1500 | 50-60 | |

| 3000horsepower | 10KV | 2250 | 60-80 | |

| 4000horsepower | 10KV | 3000 | 80-100 | |

| 6000horsepower | 10KV | 4420 | 100-160 | |

| 8000horsepower | 10KV | 6000 | 160-200 | |

| 10000horsepower | 10KV | 7500 | 200-260 |